While growing up in an African environment, “Nigeria” as a kid, each time i followed my mom to a ceremony either in church or at any ceremony ground, i would sit there carefully staring at the designs on the women’s attire.

Then boom, i start making creative imaginations out of the the lovely designs i saw on those women’s African attire lol, they were so beautiful and creative in nature such that i would create a whole new ceremony of my own all in my imagination, out of those designs on their dress, some had horses, some had fishes, some even had things like a standing fan, in my mind i’m like “like are guys joking me right now?”

Most of those designs left me thinking, “how did they even get to stamp a fan, horse, mask, fish and the rest of the things i saw on these women’s dress?”, “could this be magic?” “how are they produced?” “where are they being produced?” and lots of many other questions which i kept asking myself.

Well now i have all the answers and i’m ready to freely share it with everyone searching Google to get answers about the different kinds of African Fabric, their origin and history, how they are made, where they’re made, where you can get them, and lots more, fasten your seatbelt it’s going to be one fantastic ride into the history and mystery of African materials.

So lets take a close look at the different kinds and most popular African Fabric we have here in Africa

- Adire

- Aso oke

- Kente fabric

- Ankara fabric/African wax print

Hold on! did you also create imaginations from little things like a fish on a dress, when you were a kid? you can leave your answer in the comment section below.

ADIRE AFRICAN FABRIC

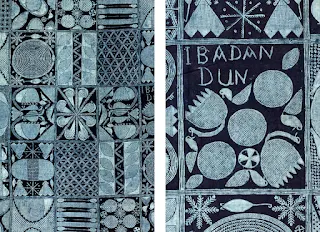

Let’s begin with a brief origin of the Adire African Fabric, many say the origin and history of the Adire African Fabric, is tied to the largest cities of Ibadan and Osogbo, in the Yorubaland’s, a place in Nigeria, West Africa. This is so because history has it that the Adire African Fabric dyeing started in Abeokuta after the Egba women returned from Ibadan with the dyeing knowledge and skill which they learnt in Ibadan.

What really happened?

The history of the Adire African Fabric goes as far back as the the 11th century in the Dogon Kingdom in Mali, where the indigo dyeing was mostly used on the caps of the indigenous people of the Dagon Kingdom. Years later the indigo dyeing pattern, known as Adire, which means “tie and die” began to spring up the ancient city of Abeokuta.

Abeokuta which was also the city and center of numerous fashion making process such as, indigo dyeing, weaving, and also the manufacturing of cotton. The Adire African Fabric had a unique place in the hearts of the people of Abeokuta, the first seen and recorded event of the production of the Adire African Fabric took place in the Jojolola Soetan’s compound, which was carried out by the famous Chief Mrs. Miniya Jojolola Soetan who was the Head of Women of the Egba land.

The tie and die pattern of making the famous Adire African Fabric, later became a generational skill and business to the descendants of the Jojola’s.

How is the Adire African Fabric made?

The traditional preparation of the Adire African Fabric had a unique pattern of production and marketing, unlike any other African fabric that was made back then, the production process requires two special women the first is known as the “Alaro” the “Alaro” is majorly responsible for the control and marketing of the Adire African Fabric, while we had the “Aladire” who was responsible for creating the resist pattern.

There were traditionally two resist pattern used to create Adire African Fabric back then, but they’re now a few more patterns that has come in over the years, these traditional two patterns were used to create either soft blue or white design which then contrast with the indigo blue saturated background of the African Fabric.

During the dyeing process the women made use of bright colors which mostly came from locally grown indigo leaves or indigo grains that were imported, the locally grown indigo leaves were usually fermented and mixed with water, there were also softened with caustic soda to create the dye.

There were large pots of dye kept at the production ground where the fabrics would be dipped in for about a minute and pulled out, the fabrics will then be kept to oxidize for a while, this could be done for a couple of times until the color blends with exactly what the producers had in mind. Most times after dyeing the fabric it will be ponded in a soft-like manner until it begins to shine or glitter.

During the creation process the women will carefully position the African Fabric in such a way that while dyeing them not all parts of the fabric will be covered in the dye, those parts left untouched by the dye will then reveal itself once the dye is dried up. The two main patterns of making the Adire African Fabric which i pointed out above are the Raffia and starch resist-dyeing patterns.

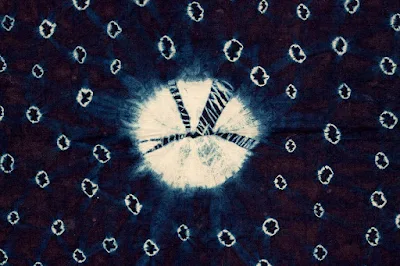

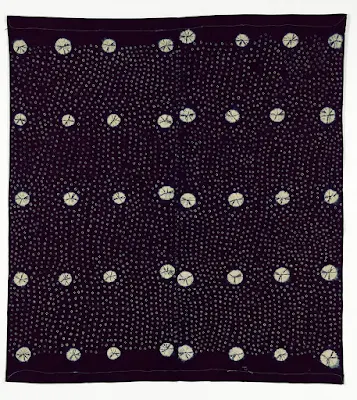

The Raffia pattern

Also known as (Adire Oniko) pattern had different way’s in which it would be applied to give different results. One of these techniques involved tying little items like cowries, seeds and stones on the African Fabric before dying them, which will reveal little circles or shapes on the Fabric after the dye has dried up. In other cases the Fabric will be bent in a way that it will form large circle in the middle or certain parts of the material.

The Starch pattern

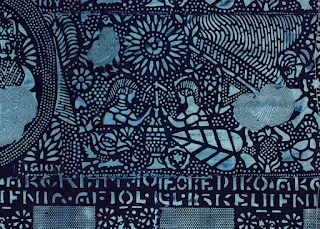

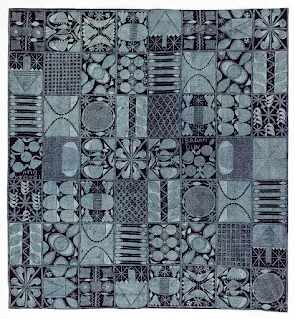

Also known as (Adire Eloko), this pattern was one of the most difficult patterns of making the Adire African Fabric, the starch on the Fabric where usually applied to only one side leaving the other side to appear as plain blue, the starch was mostly applied on the cloth by a sort of painting using some metal tools which created a variety of designs and styles on the Fabric, from here a new African Fabric would be made whole.

We also had the other patterns of making the Adire African Fabric which i mentioned above, these other patterns included

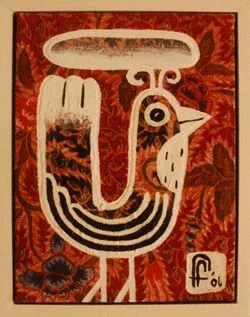

Hand painting pattern

This was also one of the difficult and time-consuming ways of making the Adire African Fabric, as it involved carefully painting the dyed materials by the woman using tools such as matchsticks, the midribs of palm leaves, chicken feathers, the painting was usually made out of square and rectangular boxes, these women would then take their time to paint out little different styles and designs to their taste.

Stitch resist pattern

Also known as the (Adire Alabare) this was simply using sewing process to resist the dye. Sewing machines and hand sewing were both used to create different kinds of designs and styles on the Fabric. This was the part where men mostly came into the production line, because they did all the sewing. In as much as the stitch pattern was unique, if the sewing was done with Raffia pattern then it would still be considered as (Adire Onike)

Now you have all the gist about the Adire African material. Lets keep going

ASO OKE AFRICAN FABRIC

Lets take a look at the meaning of the Aso Oke African Fabric, it’s history, types, and how they’re being produced.

Aso Oke according to the Yoruba people simply means “top cloth” or “cloth from the up country” it is the shorter version of Aso Llu which symbolizes a piece of cloth with very high standards, it is originally and traditionally made and worn by people of the Yoruba tribe in Nigeria, History has it that these lovely African Fabric first came about in the 15th century in Iseyin town in Oyo state in Southwest Nigeria.

Aso oke African Fabric is one that is usually worn on special occasions and ceremonies like a marriage celebrations, or burials, this African material was also mostly used to make Agbada, which are worn by men, and Fila known as caps.

The Aso Oke preparation is one unique process that takes different stages to arrive at the final product. First the cotton used to make the thread which are then used to weave this colorful African Fabric (Aso Oke) are mainly sowed and reared during the raining season from when the rain starts getting deep into the soil that’s between June and August and maybe some late planting in September. During this season the cotton are being carefully looked after, by the end of the year or early, of the next year between December and January the cotton are harvested and ready to be used.

The making process of making the Aso Oke African Fabric is referred to as painstaking, it’s made with the “Orun” a Yoruba term for spindle, a weaver is also needed to get the work done. The work begins with the cotton being separated from wool alongside it’s seed, after that the cotton being sorted till it becomes free of dirt. Once that’s done, the next thing is coloring or dying the threads to the desired colors the weaver wants, then the weaving can begin.

The threads are being arranged in sequence of colors and pattern of which the weaver wants, the neatly sorted out cottons are then filled into the spinning machine, with the help of the weaver the spinning machine is made to pull together the thread and cotton till it tightens up and begins to form the Aso Oke African Fabric, gradually the Fabric begins to come out clean and neat.

The Aso Oke African Fabric are of three main types;

- The Arari

- The Sanyan

- The Etu

The Arari consist of a deep red color, it is sometimes woven with magenta waste silk, or with synthetically and locally made cotton with some shinning threads, sometimes with perforated patterns.

The Sanyan is usually pale brown and woven from beige silk, which is mostly gotten from cocoons of Anaphe moth, it is most often used for funerals and weddings.

The Etu consist of dark indigo colors with tiny white stripes, like the color of a guinea fowl, it also represents the guinea the fowl in the Yoruba land, which equally symbolizes simplicity.

KENTE AFRICAN FABRIC

Kente is another African Fabric that catches lots of eye’s, both in time past and in contemporary society, it will be the first African Fabric on this list to have it’s origin from another African country other than Nigeria. Let’s look at it’s history/origin, the production method and the types.

The Kente African Fabric has it’s origin from Ghana a country in West Africa, Kente is gotten from the word “Kenten” in the Asante or Akan native dialect of Ghana which means “basket” or “handwoven”. In the Akan land Kente is also referred to as “nwentoma” which means woven cloth.

History has it that Kente fisrt came into existence during the 11th century, it was originally worn in form of a toga by kings and queens of the Ashanti and Ewe tribes during the 18th century.

wearing Kente

History has it that the pattern of the Kente African Fabric, came about from two brothers who went hunting, Nana Ameyaw and Nana Koragu during their hunting quest they stopped by to observe Anansi the god, who was weaving his spider web in a unique pattern. When the two brothers came back and informed the greatest weavers of the kingdom, the weavers then formed the Kente African Fabric.

Though the Kente African Fabric is unique to Africans, there various other places where Kente are being produced, we have;

- Traditional and authentic Kente Fabric, made by the ideal weavers in native Kente kingdoms

- Kente produced in China for westerners

- Branded Kente produced by brands such as Louis Vuitton, Vlisco, etc

The stripes used to make Kente are usually dyed separately based on how the weaver wants the Kente Fabric to look after production, the weaving is done with a wooden loom where the stipes or thread as put together and compressed to form a flat material with multi-colors, which is the end product of the Kente African Fabric.

There a lot unique things about the colors of Kente and it’s importance to the people of Africa

- Red symbolizes passion

- Green symbolizes earth and renewal

- Blue symbolizes purity and harmony

- Gold symbolizes status and serenity

- Yellow symbolizes fertility

ANKARA FABRIC/AFRICAN WAX PRINT

This is by far the most popular African Fabric in Nigeria, it’s one fascinating material that has caught a lot of attention over the years, we’ll be looking at it’s origin/history, how it’s being made and the different types that are available.

It’s really surprising that the popular Ankara fabric is believed to not have originated in Africa, but i’m here to clear your doubt. You see history has a way of bringing out things you never expected or believed existed. Let’s start with the popular believe and history we all know.

Ankara fabric is known to have originated from the Batik pattern of creating wax prints in Indonesia, the term Batik comes from a Javanese words “amba” and “tik” which means large dots or wide dots. So how did this whole process, name and design become a household name in Africa?

During the Dutch colonization in Indonesia the Dutch colonial master had come across the batik wax produced locally in Indonesia, they had a plan to recreate these batik Fabrics using machines that could imitate the pattern of the original batik. Samples of the batik Fabric were sent to the head quarters in Netherland, “people from Netherland are called Dutch”.

Colonization Of The Indonesians By the Dutch

When the samples of batik Fabric had gotten to Netherland, notable men such as Fentener Van Vlissingen, who inherited a cotton mill company from his father now known as “Vlisco” and Jean Baptiste Theodore started working on creating machine that could replicate these batik Fabric, they succeeded in recreating the batik materials, but the purpose to which it was created had failed in great measures. The purpose was to resell these replicated batik Fabrics in Indonesian market, this marketing process failed as a result of the lack of quality and smell of the original batik produced in Indonesia which could not be found in the ones produced in Netherland. After this great failure, came the batik Fabric in Africa

Now here’s the part most websites won’t tell you about concerning the advent of batik, batik is seen to have been first used in Egypt which is in Africa, this was during the 4th century BC, it was used as part of the mummification process in Egypt “that is really old right?” so based on history we can see that batik has some of it’s origin from Africa.

Let’s quickly look at the production process of Ankara material. In the 4 most popular African materials in Africa listed here, this very one has to be the easiest to make in history.

In the ancient art of creating Ankara fabric used in Netherland, an amber is usually applied on one side of the fabric, after that the different colors of dye is applied with the help of the amber the dye only appears on one side of the fabric, and it’s kept to dry